Customer

The customer is one of the largest food manufacturers worldwide.

Computer vision service developed by Rubius helps determine the size and shape of pet food pieces 6 times faster

The customer is one of the largest food manufacturers worldwide.

The customer found out pets prefer food of balanced-size pieces. And if there are too many large pieces in the package, pets may not finish their meal. That is why pet owners could choose products from other manufacturers. It can lead to an outflow of customers and negatively affect the company’s profits.

Previously, company employees checked the size of pet food pieces manually during the quality control stage. Every three hours, a quality control specialist would take a small part of the batch from the continuous conveyor belt and separate the longest pieces. If the number of such pieces exceeded the acceptable limit, it indicated that the cutting mechanism was not working properly.

For the next batch, the employee adjusted the parameters of the cutting mechanism and the selected pet food was sent back for processing. The checking process needed acceleration and improvement to ensure that every package has feed of required size in optimal quantity.

We have identified three main factors that cause large pieces of pet food entering the packaging:

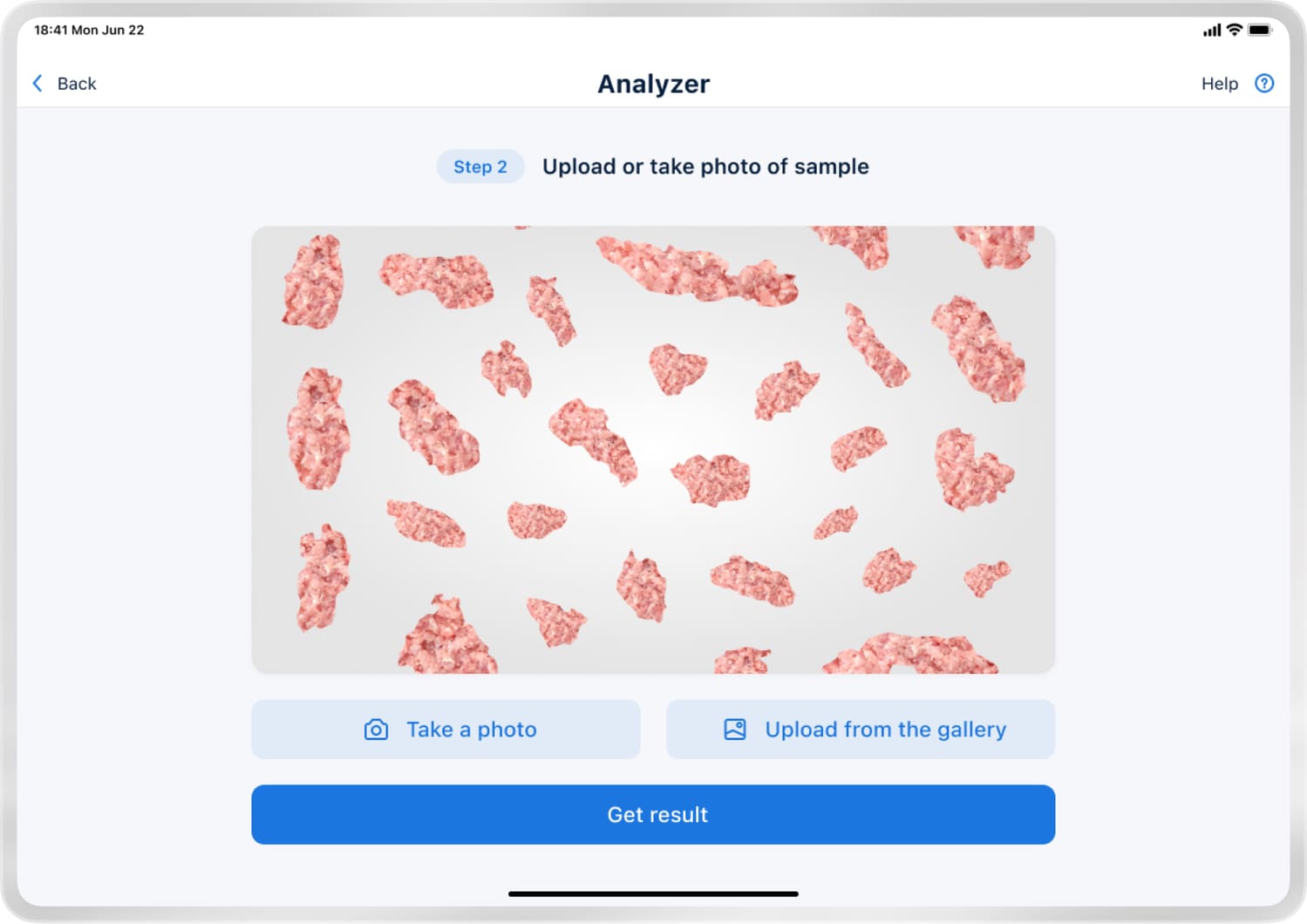

The Rubius team developed a special computer vision (CV) module for quality control of feed. The module is integrated into a web-based application which helps the specialist to track the size of food pieces based on photos from cameras located along the conveyor belt. The application can be launched on the tablet and PC.

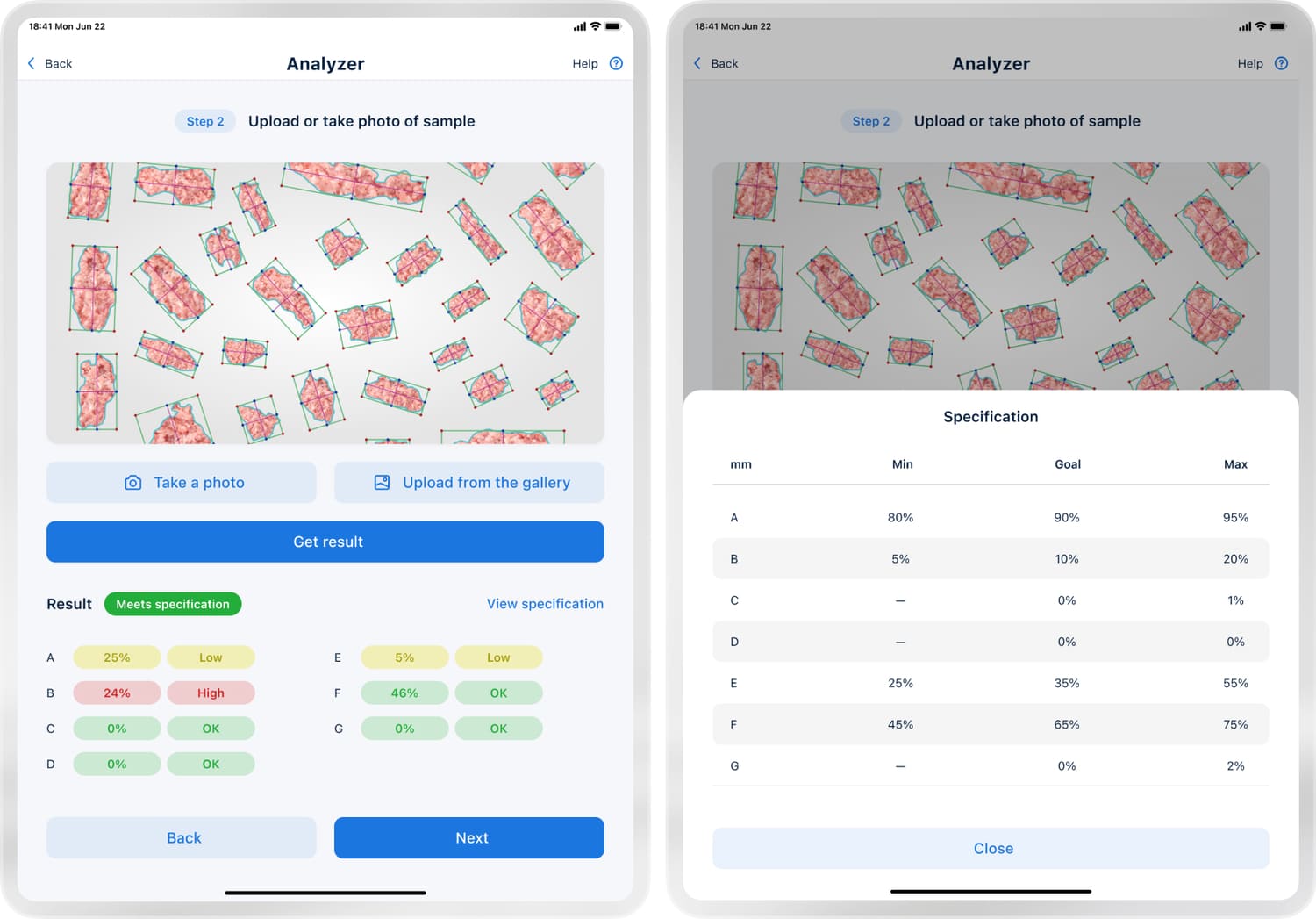

The results screen displays the following data:

For a more detailed check, the user can view the summary table with data on the specification (length, shape, area) of the pet food pieces and compare them with the acceptable values. It helps to quickly correct irregularities in the cutting mechanism and ensures that the pieces of food about the required size enter the package. The total time for verification takes less than 5 minutes.

The web application has a help feature that displays detailed instructions on how to use the application and how to evaluate pet food pieces. It also contains data on past measurements.

The CV-based web-application helps quality control specialists track the condition of the pet food at any moment of conveyor belt movement. It helps quickly identify the size of the food pieces and correct the irregularities of the cutting mechanism.

The assessment of the feed quality occurs according to the permissible indicators (length, shape, area), they do not change over time. This process gives regular and accurate results.

The system operates around the clock with the same productivity in all factories of the pet food manufacturer. This allows to increase the speed of the feed quality control by 6 times. In this way, optimal-sized pet food pieces enter the package with high accuracy. It helps to increase customer loyalty and reduces the outflow.

Tell us about your requirements and we’ll get back with a possible technical solution